Dieless robotic sheet forming is a fully digital process for forming large sheets of metal rapidly into complex contours.

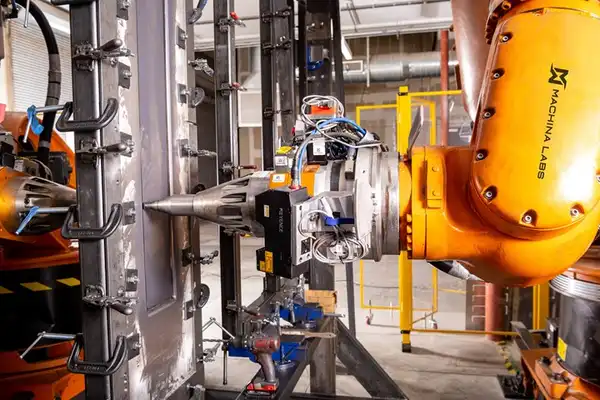

Described as dieless robotic sheet forming, the process traces its roots to 1970s-era incremental sheet forming (ISF) — some forms of which used dies and others that did not. Machina’s contributions are in application of computational modeling and simulations, machine learning/artificial intelligence (ML/AI), sensor technologies and kinematic solutions (industrial robot arms). The entire process runs off a software stack and interfaces developed by Machina. It transforms CAD files into robot tool paths and uses sensors to interpret force and torque being applied as well as optical scans measuring deformation to incrementally manipulate sheet metal to form parts. The process creates a digital twin as the part takes shape, and a digital thread captures all relevant process characterization and part qualification information. This digital record then travels with each piece produced for full documentation.

The interesting thing about Machina’s process is that it borrows elements from conventional and digital manufacturing and yet it is neither strictly subtractive nor additive. Rather, it’s a formative (or deformative) process. It builds geometry layer by layer in a matter of hours and eliminates the need for (and investment in) sequential stamping dies and presses or CNC machining centers.

Editor's Note - Machina Labs is not working with composities at this time.

Updated: November 2025

EXPLORE NEW POSSIBILITIES WITH MACHINA TECHNOLOGY