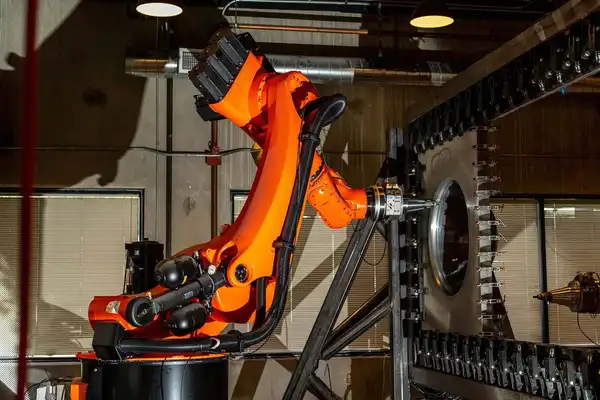

A robot forms metal sheets at Machina Labs in Chatsworth, California. Photographer: Kyle Grillot/Bloomberg

A few months ago, I stood in front of a laser scanner that made a digitized file of my head. Using that file as a guide, two gigantic robot arms set to work poking and prodding at a piece of sheet metal until they had replicated every contour of my face in fine detail. While the robots looked large and clumsy, they were able to perform the same type of precision metal shaping that has been done for centuries by skilled craftspeople. In the end, they manufactured a realistic bust I could be proud of, my own genetic limitations notwithstanding.

The bust was the work of Machina Labs, the Chatsworth, California-based startup that made the metalworking system. The company’s ambitions go far beyond doing cute things like reproducing reporters’ faces. Its primary focus is on saving industrial companies time and money by putting a robotic blacksmithing army at their disposal. “I never thought we’d see anything like this,” says Bobby Walden, the owner of Walden Speed Shop, who has spent decades hand-making custom metal parts for cars. Walden has visited the Machina factory and reckons the robots are already good enough to replicate much of what he does, only without the arthritis and back pain. “I’m looking at this robot, and my brain starts going crazy,” he says.

EXPLORE NEW POSSIBILITIES WITH MACHINA TECHNOLOGY