INTELLIGENT. AGILE. REAL METAL.

Machina Labs builds and operates elastic factories. Intelligent, agile, software-defined manufacturing that turns design intent into precise metal structures in days. Our factories use AI-guided robotics to load, form, scan, trim, finish and assemble complex structures directly from CAD. No dies. No molds. No delays.

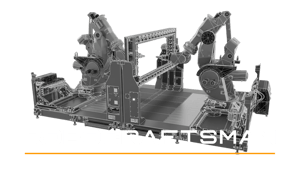

The result is speed – Go from prototype to production in one RoboCraftsman factory.

Machina Labs brings speed, flexibility, and design freedom to automotive manufacturing. OEMs and custom builders can customize production-grade body panels without tooling and in a fraction of the time to unlock mass customization at scale.

.png?width=300&name=Frame%204%20(1).png)

Machina Labs delivers Airframes-as-a-Service through deployable elastic factories. We form mission-critical skins and structures for military aircraft and weapons systems faster and without tooling to accelerate readiness across depots, installations, and forward-operating locations.

Machina Labs forms and assembles thin-walled, high-temperature alloys for advanced aerospace and defense systems. We enable rapid iteration, qualification, and production of hypersonic structures, missile bodies, and restricted programs. No tooling. No delays.

Machina Labs unlocks manufacturing for industries where metal is hard to make. From naval structures and energy systems to immersive design projects, our RoboCraftsman platform enables the rapid fabrication of precise metal structures without tooling delays or minimum volume requirements.

Machina Labs enables rapid design iteration and mass customization for the automotive industry. OEMs and custom builders can bypass tooling constraints to form production-grade metal body panels in days, not months.

.jpg?width=300&name=Screenshot%202025-09-19%20at%209.53.52%20AM%201%20(1).jpg)

Machina Labs delivers Airframe-as-a-Service through portable, Machina-operated elastic factories. We form and restore critical aircraft structures with speed and precision, supporting readiness wherever it’s needed, from program offices to forward-operating units.

Built for extreme performance, our RoboCraftsman™ platform forms thin-walled, high-temperature alloys. We support rapid iteration and qualification for hypersonics, missile bodies, and classified programs – no dedicated tooling, no delays.

Machina Labs tackles unique manufacturing challenges across industries—naval structures, energy systems, and immersive design projects. Our flexible platform forms complex metal parts fast, enabling custom fabrication without tooling delays or volume requirements

“We are excited to work with Machina Labs in bringing their advanced and agile manufacturing platform to our customers. We aim to operationalize and scale solutions with speed and effectiveness so the U.S. and our allies can stay ahead of emerging threats.”

"Innovative technologies that use sheet metal feedstock have broad applications in NASA as structural hardware, enclosures, instruments, and robotics, among others, but also for use in low-gravity manufacturing such as in Earth-orbit or on the lunar surface. Robotic micro-forging is one of the technologies that offer exciting new applications."

“We are excited about all technologies that make manufacturing, repair, modification, reclamation, and rework of aircraft and their associated components more agile, affordable, and faster. Robotic metal forming is most certainly one of those technologies.”

“At Toyota, we’ve spent decades perfecting high-volume, low-variation production. But that same efficiency makes true customization nearly impossible to deliver profitably—and customers are asking for it.

That’s why we’re excited about our partnership with Machina Labs. RoboCraftsman thrives in low-volume, high-variation environments, where every change is digital and flexible. It means faster changeovers, less capital, and personalized parts produced right alongside mass production.”

We are builders. Born from SpaceX, Relativity, Carbon3D, Novelis, and nTopology, our team brings deep expertise in robotics, manufacturing, materials, and software to build something better.

At Machina Labs, we’re creating agile, intelligent factories that form and assemble real metal, directly from digital designs. Sound like your kind of team?