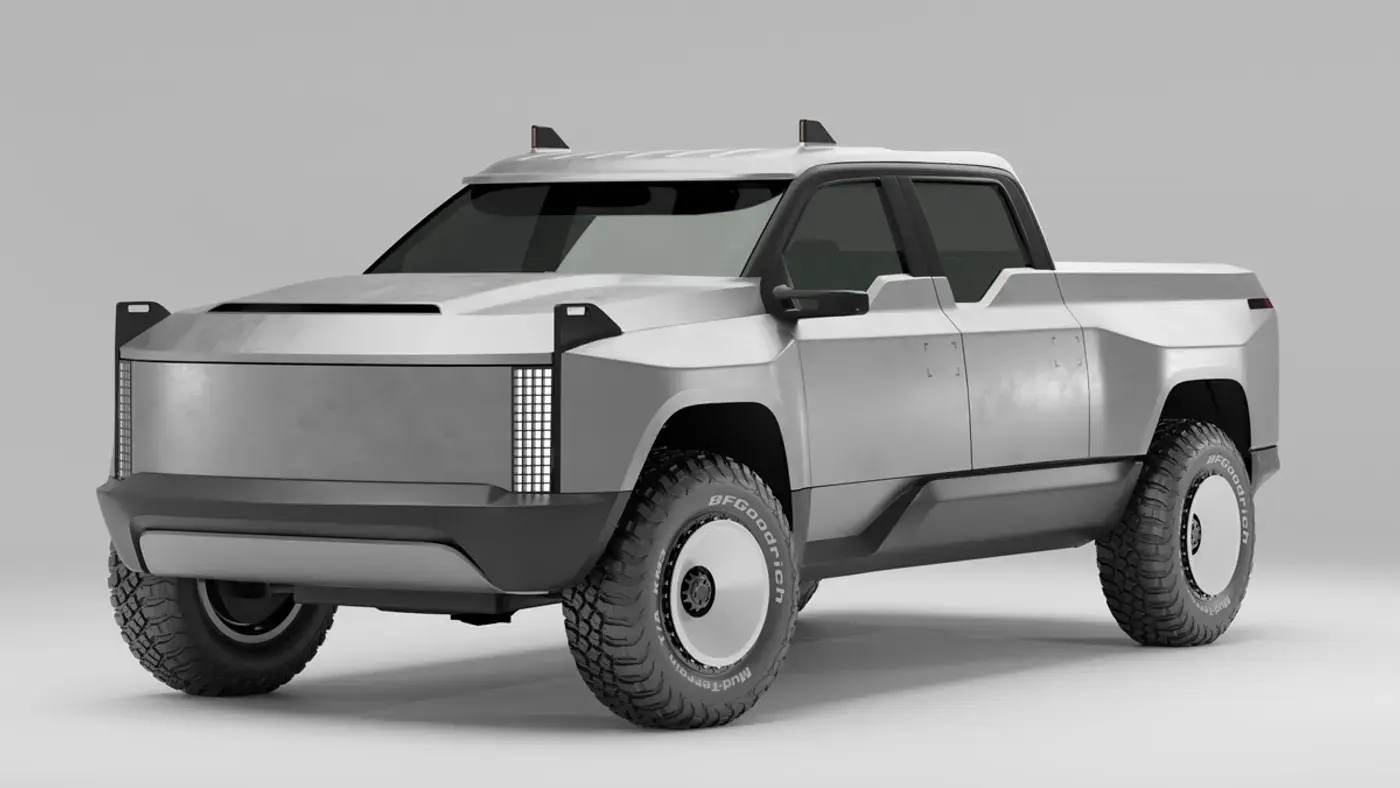

Try the configurator to:

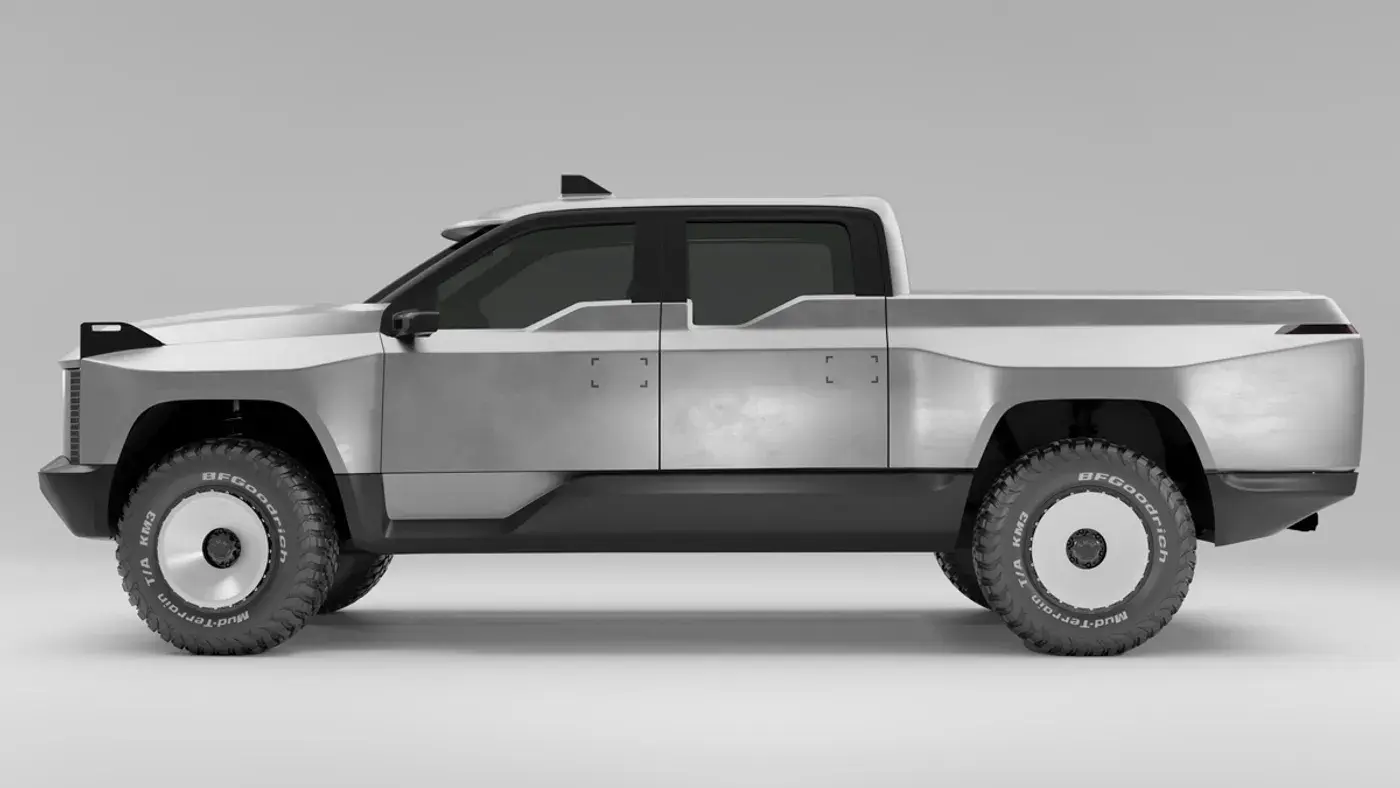

Mix and match designer panels

Upload your own graphics

Sculpt, paint, and personalize exterior forms

* Custom graphic uploads available during pre-order

* Custom graphic uploads available during pre-order

* Custom graphic uploads available during pre-order