Airframes

Expeditionary military depots that sustain aircraft and defense platforms 10X faster

A Deployable Factory at the Point of Need

Sustaining aircraft has long been slowed by lengthy lead times, limited suppliers, and tooling requirements that delay critical airframe replacement parts. Machina Labs changes this paradigm with Expeditionary Depots as a Service — portable, software-defined factories that can be deployed wherever needed. Instead of waiting months or years for qualified airframe skins and metal structures, depots and forward-deployed bases can produce them locally in days. This model reduces Mission Impaired Capability Awaiting Parts (MICAP) ratios, strengthens supply chain resilience, and ensures the Air Force, Navy, Army, and Marines can return aircraft to mission faster.

Aging airframes + obsolescence make legacy parts hard to source

Long lead times: up to 56 weeks for parts using traditional depots

Supply chain vulnerabilities: reliance on single vendors, heavy CAPEX, overseas logistics

The Sustainment Challenge

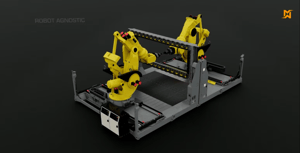

Rapid, Flexible, AI-Driven Manufacturing

Sustaining aircraft has long been challenged by lengthy lead times, limited suppliers, and tooling requirements that delay critical airframe replacement parts. RoboCraftsman changes this paradigm by enabling Expeditionary Depots as a Service — portable, software-defined factories that can be deployed wherever needed. Instead of waiting months or years for qualified airframe skins and metal structures, installations, and forward-deployed bases can produce them locally in days. This model reduces Mission Impaired Capability Awaiting Parts (MICAP) ratios, strengthens supply chain resilience, and ensures the Air Force, Navy, Army, and Marines can return aircraft to mission faster.

In addition to forming, the platform integrates a complete suite of advanced processes including roboforming, roboscanning, robotrimming and drilling, and roboheat treatment, enabling end-to-end part production in a single deployable cell. Together, these capabilities deliver unmatched flexibility, ensuring that mission-critical parts can be manufactured wherever and whenever they are needed

Why It Matters

By eliminating tooling and enabling rapid, on-demand production, Machina Labs’ Robotic Craftsman reduces downtime, lowers sustainment costs, and strengthens supply chain resilience. The system delivers mission-critical parts faster than ever before, empowering defense teams to restore readiness, adapt to evolving threats, and scale across multiple aircraft platforms with confidence. Beyond speed, the Robotic Craftsman drives significant cost advantages — reducing sustainment costs by more than $1 million per design through the elimination of part-specific tooling.

It also re-energizes the sustainment workforce by introducing cutting-edge robotics into daily operations, and enables virtual part storage, giving teams the ability to call up digital component designs and manufacture them on demand. Together, these benefits strengthen mission readiness while driving long-term operational efficiency

Questions? We have answers.

The Robotic Craftsman can produce and deliver parts in days, not months. Systems can be deployed directly at depots or forward bases to eliminate long supply chain delays

By eliminating the need for part-specific tooling, Machina reduces costs by more than $1M per design. Pricing follows a hybrid model — a dedicated capacity fee plus a variable per-part fee, aligned with sustainment needs

The system is capable of producing airframe parts in aluminum, titanium, Inconel, steel, magnesium, invar, and other refractory metals

Yes. The system was designed to support aging platforms and hard-to-source components

Built-in AI process controls and closed-loop inspection ensure aerospace-grade compliance, with robots self-correcting in real time

The Robotic Craftsman ships in an ISO freight container and can be fully operational in less than one day